Fine-tune your homogenizer to boost quality of tomato products

Her advice to customers is to review the process from time to time, and to experiment by making adjustments to the homogenizer.

Small adjustments can give marked effects

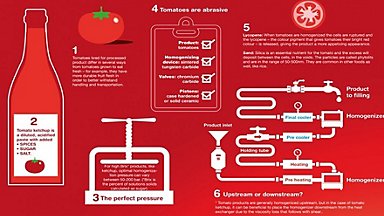

An effective homogenization of tomato juice, ketchup, sauce and paste provides a wide range of positive effects that result in a better overall product quality. These include less separation/watering off, Improved mouthfeel and Improved colour.

“One thing you can very easily change is to increase or decrease the pressure and see what happens,” advises Jonsson. “Many tomato processors are very aware of their consumption of electricity and cooling water. You could test if you can reduce the pressure and still have a satisfactory product quality. In that way, you can save money and wear on the parts, and make as small a footprint as possible.”

One of the trends driven by consumers is the desire for a tomato ketchup with a ‘clean label’ (one with as few artificial additives as possible). By increasing the pressure, it may be possible to remove stabilizers such as CMC (carboxymethyl cellulose) and still achieve the same product quality as before.

One final tip from Jonsson is that if the homogenizer is upstream of the heat exchangers, it may be worth moving it downstream to avoid turbulence and pumping. Excessive shear after homogenization can adversely affect the viscosity and mouthfeel of ketchup and tomato pastes.

Sign up to download the report

To learn more about the efficient homogenization of tomato products including seven key benefits of the process, fill in your details to receive a useful report